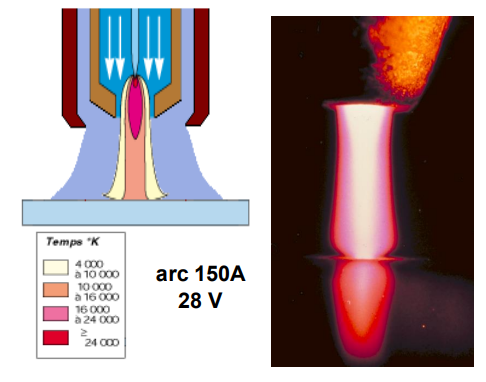

DID YOU KNOW?????? TIG (Tungsten Inert Gas Welding) is a widely used Welding process, with certain additions to the process the intensity of the welding ARC could be enhanced. The Enhanced ARC allows the parameters such as speeds (Travel Speed) to increase thus enhancing the material properties. Lincoln’s Plasma TIG Process works by ionisation of an Inert gas between Tungsten (a Refractory electrode) & the part to be weld. Lincoln’s Plasma is constricted either mechanically or pneumatically by way of a nozzle through which the Arc is forced to pass. This process helps in the development of energies which are significantly higher while increases the welding performance. Lincoln’s Plasma TIG process can be used to weld on Steel, Stainless Steel, Titanium, Duplex, Inconel, etc. It provides you up to 6mm max thickness for carbon steel & butt joint preparation according to the quality of the raw material. Some of the benefits of the Lincoln’s Plasma TIG Process are: • Easy to implement, Low Distortion • Excellent appearance of the Weld Bead • Reduction in preparation Time: Elimination of Bevel • Reduction in Welding Time • Complete & Regular Penetration • Outstanding Overlap & Weld finish Quality And much more… We at Weldflow Engineers gives you the best customer satisfaction. We are here to answer your every query regarding products. Call us on 8048031990 or drop us an email on sales@weldflowengineers.com Weldflow Engineers, An Authorized Distributor for The Lincoln Electric Company Content by Aniket Jadhav Weldflow Engineers #LincolnElectric #LincolnWelding #LincolnWelders #WeldWithLincoln #LincolnWeldingSolutions #LincolnWeldingEquipment #LincolnWeldingTechnology #LincolnWeldingExpertise #LincolnWeldingInnovation #LincolnWeldingQuality

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2023-07-11T05:41:40

DID YOU KNOW?????? TIG (Tungsten Inert Gas Welding) is a widely used Welding process, with certain additions to the process the intensity of the welding ARC could be enhanced. The Enhanced ARC allows the parameters such as speeds (Travel Speed) to increase thus enhancing the material properties. Lincoln’s Plasma TIG Process works by ionisation of an Inert gas between Tungsten (a Refractory electrode) & the part to be weld. Lincoln’s Plasma is constricted either mechanically or pneumatically by way of a nozzle through which the Arc is forced to pass. This process helps in the development of energies which are significantly higher while increases the welding performance. Lincoln’s Plasma TIG process can be used to weld on Steel, Stainless Steel, Titanium, Duplex, Inconel, etc. It provides you up to 6mm max thickness for carbon steel & butt joint preparation according to the quality of the raw material. Some of the benefits of the Lincoln’s Plasma TIG Process are: • Easy to implement, Low Distortion • Excellent appearance of the Weld Bead • Reduction in preparation Time: Elimination of Bevel • Reduction in Welding Time • Complete & Regular Penetration • Outstanding Overlap & Weld finish Quality And much more… We at Weldflow Engineers gives you the best customer satisfaction. We are here to answer your every query regarding products. Call us on 8048031990 or drop us an email on sales@weldflowengineers.com Weldflow Engineers, An Authorized Distributor for The Lincoln Electric Company Content by Aniket Jadhav Weldflow Engineers #LincolnElectric #LincolnWelding #LincolnWelders #WeldWithLincoln #LincolnWeldingSolutions #LincolnWeldingEquipment #LincolnWeldingTechnology #LincolnWeldingExpertise #LincolnWeldingInnovation #LincolnWeldingQuality

2023-07-11T05:41:40

Keywords

- way

- butt

- part

- query

- Bevel

- sales

- Duplex

- nozzle

- speeds

- Content

- Inconel

- Complete

- benefits

- Titanium

- energies

- products

- intensity

- Reduction

- additions

- Weld Bead

- parameters

- ionisation

- Elimination

- welding ARC

- development

- Travel Speed

- carbon steel

- raw material

- Aniket Jadhav

- Low Distortion

- LincolnWelders

- Stainless Steel

- WeldWithLincoln

- LincolnElectric

- Welding process

- preparation Time

- joint preparation

- Weldflow Engineers

- Plasma TIG Process

- Regular Penetration

- welding performance

- Weld finish Quality

- Outstanding Overlap

- material properties

- to 6mm max thickness

- Excellent appearance

- Refractory electrode

- LincolnWeldingQuality

- Authorized Distributor

- LincolnWeldingSolutions

- LincolnWeldingEquipment

- LincolnWeldingExpertise

- LincolnWeldingTechnology

- LincolnWeldingInnovation

- best customer satisfaction

- Tungsten Inert Gas Welding

- The Lincoln Electric Company

Submit Your Enquiry